|

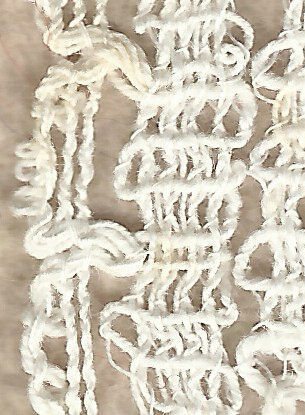

This are the picots in the main part of the lace.

Lacemakers may cut corners, but if they have two thread picots, they do at least twist the pair! Here, the two threads have been made into loops without twisting, so they separate.

The picots are on something supposed to be legs. There is no sign of plaiting. The threads are held together by narrower threads, visible near the top.

The cross-overs look odd, with threads going in various directions - not showing the neatness of the Lazy Join.

There are different lines, top right and bottom left, which at least show evidence of the weaving effect. It is difficult to day whether these are intended to be tallies or legs. They do not work either way. You can see a pair of threads weaving back and forth. A Bobbin lace tally would only have one thread, and the weave would be much tighter. A bobbin lace leg would have a plait effect, using all four threads. Looking carefully, you can see thinner threads holding the thicker threads together.

|