In the descriptions below, C means cross and T means twist.

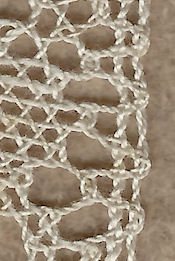

The footside is the straight edge of the lace. It is strongly made, so it can be used to sew onto fabric. This is a cloth footside. It is used in Bedfordshire and Bucks Point lace, and elsewhere. The workers use cloth stitch (CTC) to go through the passives, then the workers swap with the edge pair with cloth stitch and twist (CTCT). The pin is put inside of both pairs, rather than between them (as is more usual). Then the previous edge pair becomes the new worker pair, and works back through the passives in cloth stitch.

Click here for a description of how cloth footside is done, with an animation.

Click here for the whole piece of lace.